Plasticizer Raw Material

What Is A Plasticizer Raw Material

As the professional manufacturer, Shanshan high quality Plasticizer raw materials are mainly divided into two categories: traditional petroleum based raw materials and increasingly valued bio based and new environmentally friendly raw materials. Plasticizers themselves refer to a type of material added to other substances to enhance their flexibility, processability, or ductility. Although in a broad sense, adding water to clay or lime to concrete during pottery making can also be considered as plasticizing, this term usually specifically refers to additives used in the plastic industry. According to the definition of the International Union of Pure and Applied Chemistry (IUPAC), plasticizers are substances that achieve the above functions by reducing the viscosity of the material melt, lowering the secondary transition temperature or elastic modulus.

WHAT ARE THE FUNCTIONS OF PLASTICIZERS?

Shanshan Plasticizer Raw Material are magical little additives that make plastics more flexible and workable. They do this by reducing the viscosity of the polymer, allowing it to bend, stretch, and mold without breaking. Their key functions include:

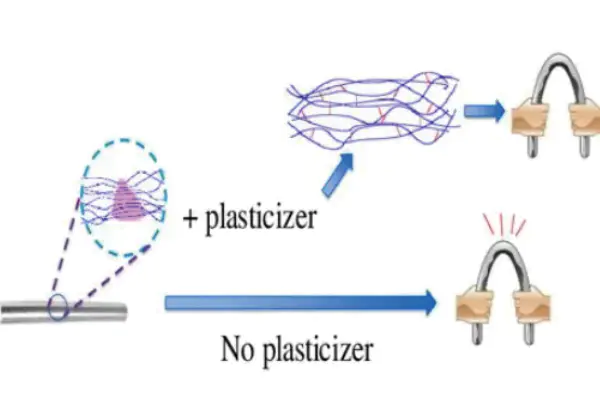

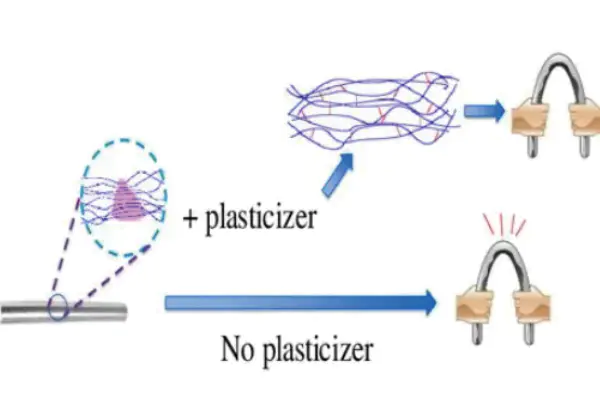

1.Increasing Flexibility: Making rigid materials soft and bendable.

2.Enhancing Ductility: Improving the material's tensile properties and impact resistance.

3.Improving Processability: Lowering processing temperatures and increasing molding efficiency.

4.Lowering the Glass Transition Temperature (Tg): Enabling the material to remain soft at room temperature.

5.Working Principle: These functions are achieved because plasticizer molecules insert themselves between polymer chains. This weakens the intermolecular forces, increases the free volume for chain movement, and consequently reduces the material's rigidity and hardness.

What are the selling points and advantages of plasticizers?

The core selling points of modern Plasticizer Raw Material lie in their ability to unify performance, safety, and cost-effectiveness.

Shanshan factory’s Plasticizer Raw Material fundamental function is to impart excellent flexibility, processability, and durability to rigid plastics (like PVC), enabling a wide range of applications from flooring to hoses. However, the most significant market advantage now stems from "Safety and Eco-Friendliness." As global regulations tighten, traditional phthalates are being strictly restricted due to potential health risks.

This plasticizer is clearly "Non-Phthalate" and complies with authoritative certifications for food contact, toys, and medical-grade applications (e.g., FDA, EFSA, REACH), providing reliable regulatory assurance. It utilizes bio-based raw materials (such as soybean oil) with biodegradable potential, reduces carbon footprint, and helps meet brand owners' ESG (Environmental, Social, and Governance) goals. Its low-toxicity attributes throughout the entire value chain ensure safety for production workers, consumers, and the environment.

From a commercial perspective, while offering high safety, these new-generation plasticizers also pursue application efficiency. They can lower processing energy consumption, and some products even double as stabilizers, helping customers reduce overall formulation costs.

Therefore, the core selling proposition has evolved from simply "softening plastics" to "optimizing plastic performance in a safe, environmentally friendly, and efficient manner," making them a key component in the green transformation of the plastics industry.

How to select the right grade for plastics?

The following four points are guidelines for selecting plasticizers for specific application needs

1. For compliance and safety (products related to food, children’s toys, medical devices, and exports to Europe and America), environmentally friendly non-phthalate plasticizers can be selected. Representative products include DINCH, citrate esters (such as ATBC), and epoxidized soybean oil (ESO). These comply with the strictest regulations and are essential for market access.

2.For general and economical applications (used in ordinary daily necessities, building materials, and domestic products where cost is a key concern), conventional types can be chosen. Representative products include DOTP and DINP (note: regulatory restrictions apply). This category offers the best cost-effectiveness while meeting basic performance requirements.

3. For durable and long-lasting (used for automotive interiors, wires and cables, outdoor products, requiring high temperature resistance, volatilization resistance, and migration resistance). High performance durable products can be selected. Representative products include polyester, trimellitic acid ester (TOTM) with high molecular weight and difficult migration, which ensures long-term stability of the product in harsh environments.

4. For special functions (requiring characteristics such as biodegradability, cold resistance, flame retardancy, etc.) should be selected. Representative products for special functions include bio based biodegradable types, adipic esters (cold resistance), and phosphate esters (flame retardancy). These types are designed to solve a specific technical problem.

In summary, The modern plasticizer is not just a tool to soften plastic but a strategic component enabling safe, environmentally compliant, and economically viable material solutions. The choice ultimately aligns with the target market's regulatory landscape and the required safety profile of the final product.